In Fukushima prefecture on Thursday & Friday with 15 journalists & influencers for a press tour, I discovered its Fukushima Innovation Coast Framework and witnessed some of its impacts: one of the world’s largest renewable-energy-driven hydrogen facilities, muscle suits, rice-based resins… This exciting & fascinating third visit since the devastating disasters of 2011 (first as a supporting tourist then as a Hope Tourism consultant) showed a clear shift toward the future. You’d find it particularly interesting if you are a researcher, entrepreneur or investor.

I’m grateful to Jarman International for its invitation and to the locals for their coordination. Below, I introduce key facilities & technologies. Most information was published during the trip in a BlueSky thread.

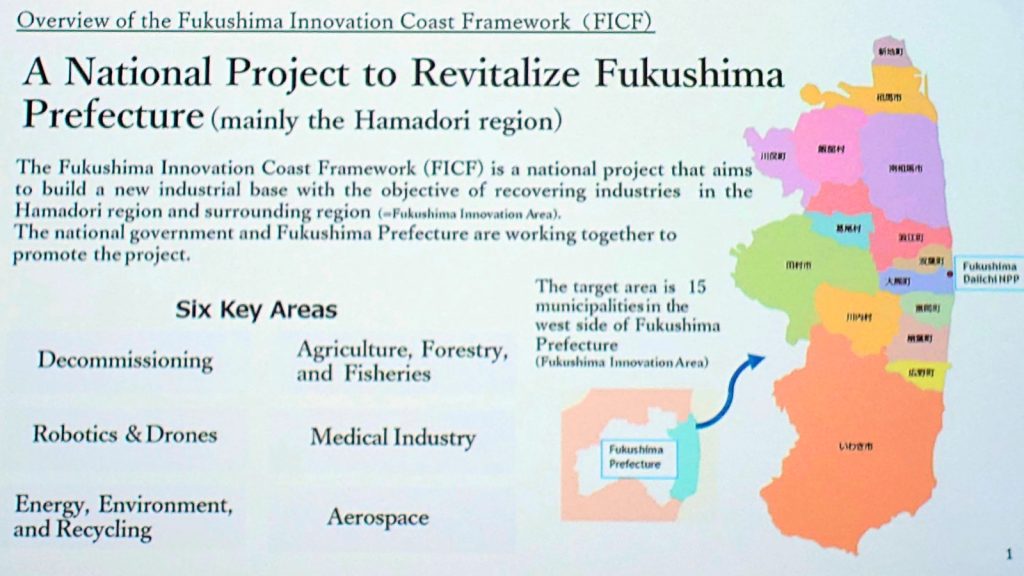

Fukushima Innovation Coast Framework

A driving force behind local revitalization is the Fukushima Innovation Coast Framework (FICF). Managed by the Fukushima Innovation Coast Promotion Organization (FIPO), this national project is transforming the “Hamadori” east coast of Fukushima prefecture into a high-tech industrial hub.

Welcoming nationals & foreigners alike, Fukushima Innovation Coast Framework is an engine for economic recovery. Since 2017, 428 companies have created 4,823 jobs in Hamadori. The framework supports entrepreneurs & businesses through site introductions, consulting, and substantial subsidies (up to 10 million yen for startups and location subsidies capped at 80% of initial investment). It also supports later stages such as R&D commercialization with subsidies up to 700 million yen.

From hydrogen-fueled drones and ultra-small rockets to muscle suits, the recipients of FICF support are building the future. 200+ companies have already benefited from its networking and intellectual property strategy support. Notable innovations include radiation-tolerant cameras now used by the International Atomic Energy Agency (IAEA) and Japan Aerospace Exploration Agency (JAXA).

F-REI & The “California Of Japan”

A highlight of the press tour was the introduction to the Fukushima Institute For Research, Education, And Innovation (F-REI). Vice President Takaya’s inspiring vision is to transform the Hamadori region into an innovative & fertile hub akin to California!

F-REI pioneers R&D that is unique to Fukushima’s context but applicable worldwide:

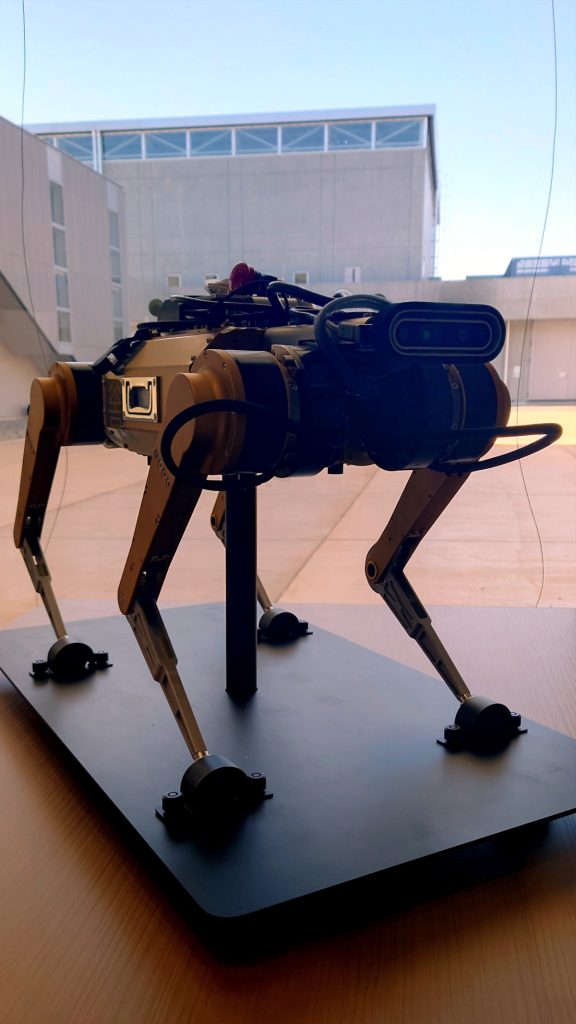

- Nuclear disaster response: data analysis, decommissioning robotics… Applications extend to natural disasters and outer space.

- Environmental restoration: contaminated/impoverished soil rejuvenation, negative-emission energy…

- Life sciences: cancer diagnostics, radiations to study agricultural growth…

- Robotics: automation for harsh environments, solutions for an aging/shrinking population…

The institute shall expand to 50 research groups by 2030, driving societal change through applied research.

Fukushima Robot Test Field

The Fukushima Robot Test Field (RTF) is an exceptional facility in Hamadori. Owned by F-REI and managed by FIPO, it’s the largest base for the development, test and standardization of land, sea, and air mobilities/robots worldwide! Since 2017, it has enabled 1,316 tests…

The infrastructure is designed to simulate common & extreme reality. It features a mock-up plant, submerged houses, a bridge, tunnels, a muddy ground, and a debris field for landslide simulations. It also includes an airfield enclosed in nets for safe testing, and a runway for 13km flights over land & sea (with 8 emergency landing sites).

Interestingly, Fukushima (along with Nagasaki) is a National Strategic Special Zone for drones since 2024. Here, softened regulations in the Civil Aeronautics Act notably allow drone delivery of food & medicine.

Complementary investments or rule changes needed? As expected, use is possible even in cold weather and on rainy days. Surprisingly however, the facility does not feature cameras in water tanks, and does not allow night testing despite Japan’s Self-Defence Forces training for disaster response there.

Zip Infrastructure: Zippar

We approached a prototype of Zippar autonomous electric cable car by Zip Infrastructure, unfortunately a month too early to ride the slope-test line. Capable of curving/branching, Zippar is as flexible as trains but cheaper (10% of train costs); it is also immune to the traffic jams that affect buses.

Zip Infrastructure chose FICF for its research and development because tests require expansive flat land available in Hamadori. As Japan’s workforce shrinks, auto-drive technology is a significant asset. Commercial readiness is expected in a few years, with potential deployments in bay areas, factory complexes, and shopping districts. Kanagawa prefecture is already interested but Osaka’s casino (2030) may first feature this technology. Discussions are underway for international deployment (Philippines…), with all units adhering to Japan’s stringent earthquake safety standards.

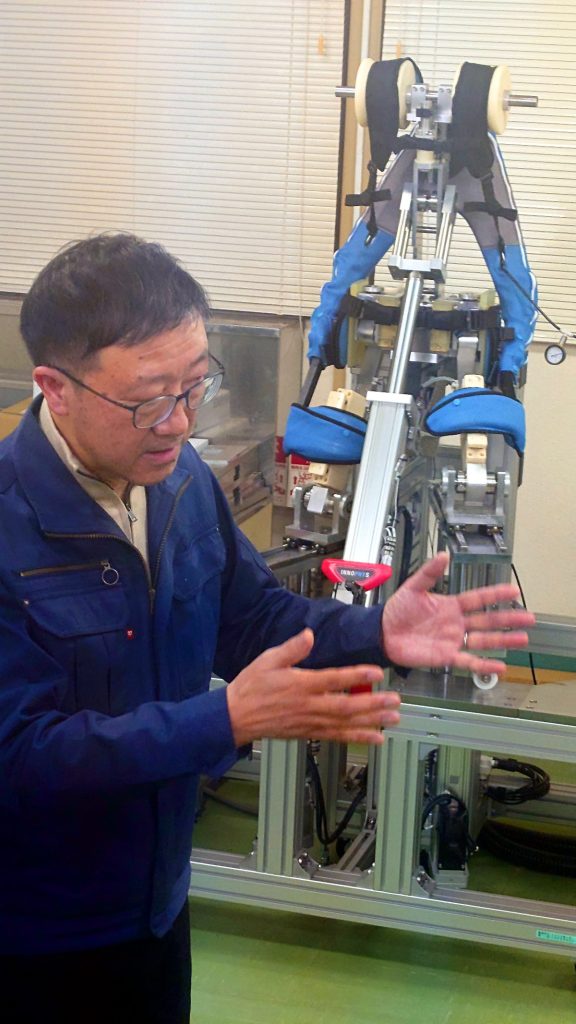

Innophys: Muscle Suits

As my PhD thesis related to smart clothing, I found Innophys fascinating. Unlike its famous competitor Cyberdyne (which relies on batteries), Innophys uses air pressure technology for its “Muscle Suits” (also introduced as “Assist suits for lower-back support”).

Innophys’ exoskeletons & supporters significantly reduce the burden on the lower back. Wearing the “Soft-Power” supporter for an easy lift at the Hamadori factory, I immediately felt its 35% burden reduction. The flagship “Every” suit is water-resistant, dirt-resistant, and ISO13482 certified (international safety standard for personal care robots).

Thanks to FICF, Innophys has already sold 35,000+ units in 20 countries. Beneficial in places as diverse as Japanese farms and waste treatment sites, French warehouses & factories, and nursing homes in northern Europe, they enable safer & healthier work, for longer durations, regardless of age. Current R&D strives to lighten/compact exoskeletons and to create rehabilitation suits.

🧵11/ Innophys' exoskeletons/supporters are notably used at farms & waste treatment sites in #Japan (+ rented to the public), warehouses in France, nursing homes in northern Europe… Its main challenge? Making exoskeletons lighter and more compact. Its ongoing #R&D? Rehabilitation suits! #TechForGood

— Sébastien Duval (@sebastienplus.bsky.social) 22 November 2025 at 07:49

[image or embed]

Prices in Japan:

- High mobility but weak support, the supporters cost 27,500 to 59,400 yens.

- Strong support but low mobility, the exoskeletons cost 149,600 to 214,000 yens.

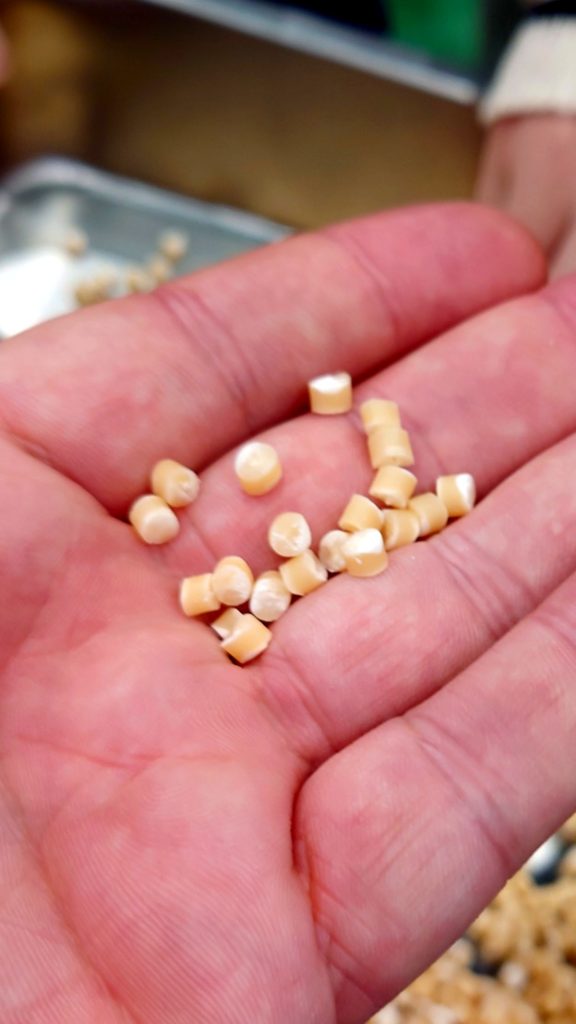

Rice Resin

Rice Resin‘s approach to community support and sustainability moved me. This company manufactures resin granules from rice that consumers shun: rice grown in Fukushima, and old rice stocks kept for emergencies by the Japanese government (won through auctions, otherwise burnt).

The process is energy-efficient, converting rice to resin in minutes over a few metres and cutting CO2 emissions by 40-57%! Major uses & clients include cutlery for Mos Burger (1,311 restaurants nationwide), garbage bags for municipalities & events… May forward-looking organizations use Rice Resin to replace hard-to-phase-out plastic: medical devices, rice ball wrappings…

Japanese & foreigners alike are welcome to visit the Hamadori factory (with appointment), especially if they are interested in partnering or investing to help decarbonize societies worldwide. Rice Resin currently operates at 50-60% capacity, and can theoretically extend to neighbouring land if needed.

Rice Resin received a revival & creation award from Japan’s Reconstruction Agency in February! In 2026 & beyond, it will keep improving its products through R&D notably regarding microplastics.

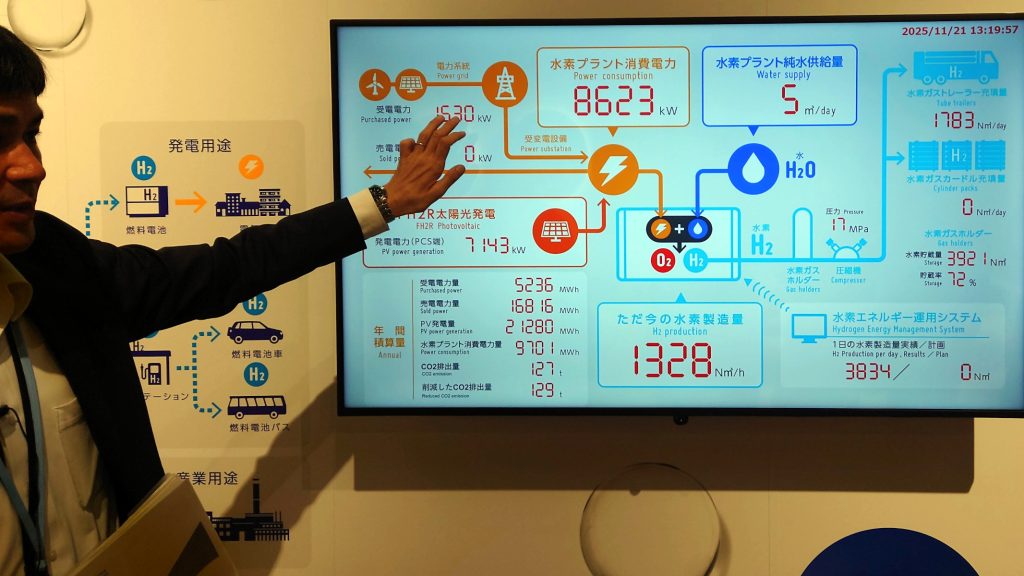

Fukushima Hydrogen Energy Research Field

For years, I wanted to visit Fukushima Hydrogen Energy Research Field (FH2R) so I felt blessed with this press tour. Former world №1, it produces up to approximately 2,000N㎥/h “green” hydrogen from its 180,000㎡ solar farm, used daily by companies in Fukushima, neighbouring Sendai and distant Tokyo. This quiet, safe environment reflects the massive innovations that happened and keep happening there.

At only 12.1%, Japan ranks 35th worldwide in energy self-sufficiency. Consequently, its vision of a hydrogen society and facilities such as FH2R are vital for national security and climate action. The two biggest challenges are interconnected: reducing costs and scaling adoption.

Beyond

Hamadori is becoming a global leader in innovation while rebuilding from its triple disaster (M9.1 Tohoku earthquake + tsunami reaching 40m-high land + nuclear meltdowns). This press tour in Fukushima prefecture confirmed that opportunities are immense for researchers, entrepreneurs or investors looking for cutting-edge technology. I look forward to discovering even more progress over the coming years!

Next time, I hope to visit:

- TEPCO Fukushima Dai-ichi (otherwise Dai-ni) nuclear power station.

- Fukushima prefectural Hama agricultural regeneration research centre.

- Farm & factory Tamura.

- Katsurao smart community project facilities.

- Manyo-no-sato wind farm.

- Nexus farm Okuma.

- Tamura biomass power plant.

- I’d also be interested in learning more about OWB, dedicated to creating 100 businesses to solve 100 local problems.

Related Publications

- Comments from pros on my related LinkedIn post.

- Photo of our group during the visit, in the January 2026 gallery of the Japan Times.

- Articles by participants:

- “Inside Fukushima’s innovation hub: From solving traffic with ropeways to turning rice into plastic” by Hana Victoria Shiraishi on Deep Japan (January 2026).

- “Why renewable powerhouse Fukushima is also pursuing hydrogen” by Annelise Giseburt in the Japan Times (February 2026).

- [PENDING] Report on the website of Jarman International.